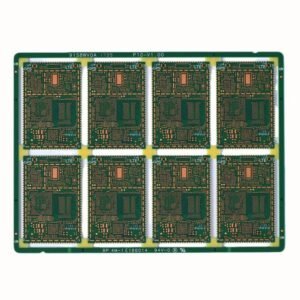

Professional PCB Assembly Services from prototype to high-volume production

HUASUN provides professional PCB assembly services and customized PCB assembly solutions, equipped with four high-speed SMT production lines, cutting-edge placement machines, reflow ovens, and a full suite of testing equipment. We offer a one-stop turnkey solution covering everything from prototype prototyping to mass production, component procurement, testing, and logistics support.

What is the PCB Assembly Services?

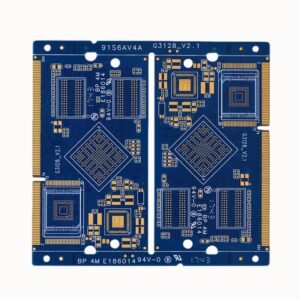

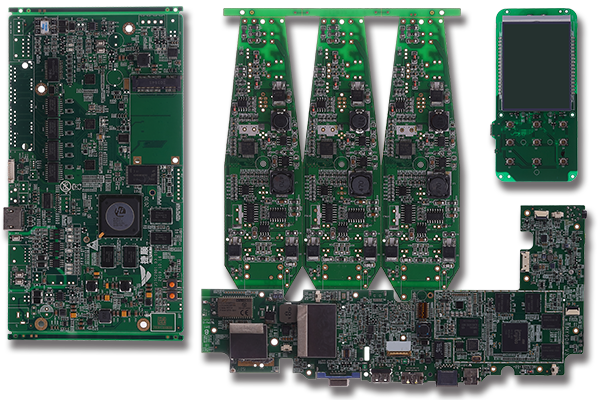

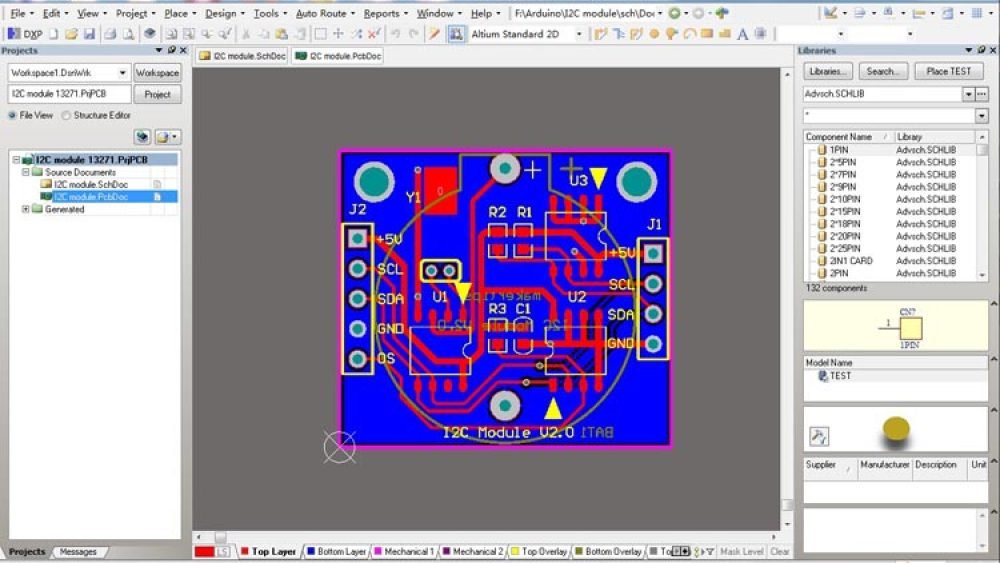

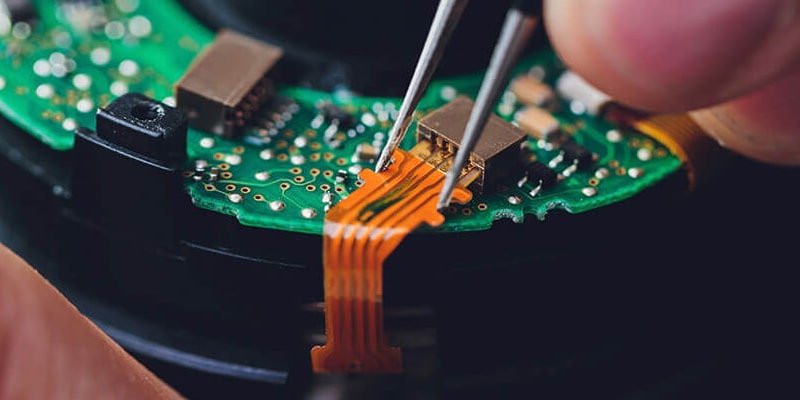

PCB Assembly Services (also PCBA services) in the electronics manufacturing services industry are probably the most recognized service and PCB Assembly speaks for itself. In this specialized service, electronic elements—resistors, capacitors, chips, LEDs and other sensors—are accurately mounted on a blank PCBs (Printed Circuit Boards) using SMT (Surface Mount Technology) or through-hole soldering techniques.

Following this step, the boards are tested and debugs to deliver a fully functional PCBA (Printed Circuit Board assemblies). In simple terms: A PCB is “bare board”, a “finished board with components assembled” is a PCBA, and PCB Assembly Services take it from “bare board” to “finished board”—the service includes assembly and testing services.

Our Main PCB Assembly Services

20+ Years Assembly Experience,10M+ Components Placed Daily,99.5% Assembly Yield Rate

SMT Assembly

High-speed surface mount technology (SMT) and its assembly services,High-speed SMT production lines with advanced placement

Full Turnkey Assembly

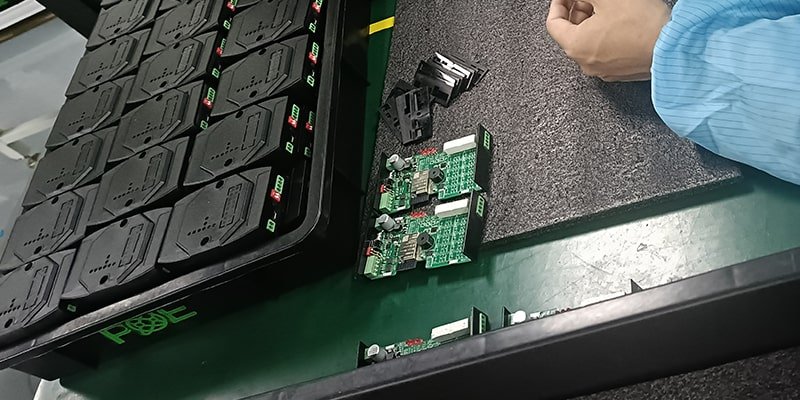

Complete turnkey one-stop service: PCB procurement, component sourcing, assembly, testing & delivery – no extra coordination needed.

Through-Hole Assembly

Reliable assembly for through-hole components (connectors, terminals, inductors) for power-related PCBs (DC24-30V lighting control boards).

Consigned Assembly

Consigned Assembly Work with your own PCBs/components – scope for your custom aquarium/LED project.

Prototype & Low-Volume Runs

Prototype & Low-Volume Runs Rapid turnaround (24-48hrs) prototyping service for new PCB designs (eg. sunrise-sunset control boards).

Testing & Quality Control

Testing & Quality Controls Functional test (FCT), In-circuit test (ICT), visual inspection – 100% working PCBA.

Why Choose HUASUN PCB Assembly Services?

- PCB Assembly Services Source Manufacturer,Over 20+ years PCB assembly service manufacturing

- New orders have no MOQ– even 1 piece qualifies for wholesale pricing,Also provide small-batch rush service

- 100% Electrical Test (E-test) and Automatic Optical Inspection (AOI), compliant with IPC-A-610 Class 2/3 standards

- Offer a turnkey solution for the entire process of PCB Fabrication + Component Sourcing + Assembly + Testing + Delivery

Equipment For PCB Assembly Service

Seamless board feeding system,120K CPH precision assembly,Vision-guided accuracy,Ultra-precise component placement,Real-time quality monitoring,10-zone temperature control,Automated defect detection

SMT Production Lines

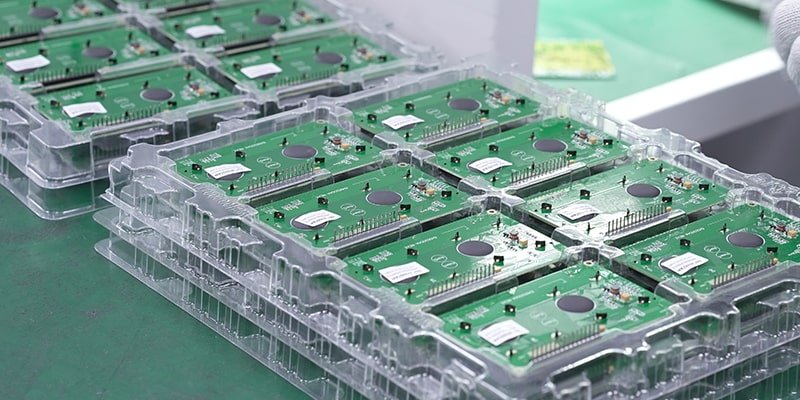

Our factory operates 5 SMT production lines with a monthly capacity of 1.5 million PCBA units,10 million placement points capacity

Pick-and-Place Machine

10 Samsung High-Precision Pick-and-Place Machines, enabling us to handle high-volume PCBA orders.

Fully-Automatic Screen Printer

Our PCBA factory is equipped with 6 GKG Fully-Automatic Screen Printers, ensuring high-precision solder paste application for every PCB.

5 AOI Inspectors

5 AOI Optical Inspection Machines to detect soldering defects and component placement errors.

Zone Reflow Ovens

Our SMT lines are equipped with Two Jinto 10-Zone Reflow Ovens to ensure stable soldering quality for high-complexity PCBs.

KCL Air Compressor

Our PCBA workshop is equipped with a KCL Air Compressor System to supply stable compressed air for SMT equipment.

PCB assembly capabilities

| Capability Item | Details |

|---|---|

| SMT Lines | 5 Lines - High-speed SMT production lines with advanced placement |

| Component Size | 01005-BGA - From micro components to large BGAs and connectors |

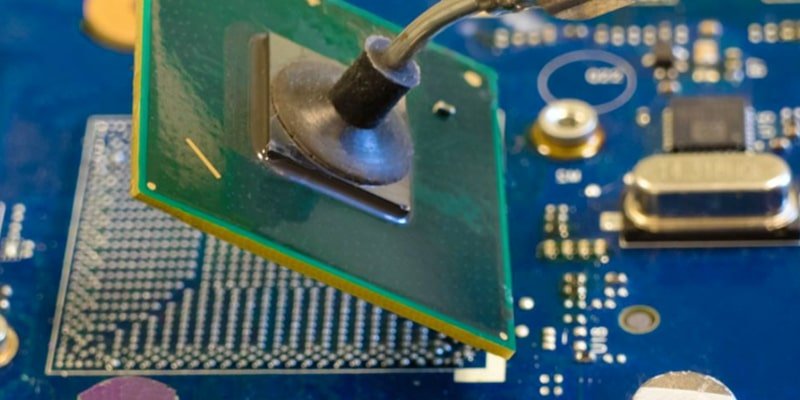

| Placement Accuracy | ±0.02mm - Ultra-precise component placement for fine-pitch devices |

| BGA Pitch | 0.3mm Min - Fine-pitch BGA and micro-BGA assembly capability |

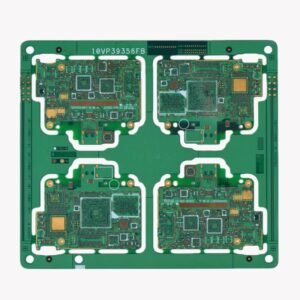

| Assembly Types | SMT/THT/Mixed - Complete assembly solutions for all technologies |

| Daily Capacity | 500K+ CPH - High-volume production with consistent quality |

| Testing Methods | ICT/FCT/AOI - Comprehensive testing and quality assurance |

| Board Size | 5×5-500×400mm - Flexible board size handling from small to largee |

| Lead Time | 3-10 Days - Fast prototype to production assembly turnaround |

Other PCB Assembly Services

——State-of-the-art SMT lines and precision placement equipment,IPC-A-610 certified assembly with comprehensive testing

- High Volume Assembly:Mass production assembly with cost optimization

- Flexible PCB Assembly:Specialized assembly for flexible and rigid-flex PCBs

- BGA Assembly:Fine-pitch BGA and micro-BGA assembly services

- Box Build Assembly:Complete system integration and enclosure assembly

Our PCB Assembly Expertise Covers

FAQ

1、What is the MOQ for PCB assembly? Do you support small-batch prototyping?

We have no minimum order quantity restrictions. We accept orders as low as 1 sample piece and support small-to-medium batch production (10-10,000 pieces), perfectly accommodating product R&D prototyping, small-batch trial production, and bulk supply needs.

2、What information is required to request a PCB assembly quote?

① PCB Gerber files + BOM (Bill of Materials)

② Assembly requirements (SMT/THT/mixed assembly, special process instructions, etc.)

③ Order quantity, whether you require component sourcing service, and the product delivery schedule. We will communicate the accurate quote within 24 hours.

3. What PCB types and assembly processes do you support?

We support assembly on all sorts of substrates including rigid PCBs, flexible PCB, aluminum substrate, HDI PCB, etc. Assembly processes cover SMT, THT, mixed assembly, with capabilities for placing precision components such as 01005 micro-components, BGAs, QFP, etc.

4、Can we supply our own components or must you source them?

Both contracting options are available:

① Contract manufacturing: You provide PCB boards, components, and we handle assembly + testing only.

② Full turnkey service: We manage PCB fabrication, components, sourcing, assembly + testing for one-stop delivery. Options for brand selection recommendations for sourced components are offered by us.

5、What is the typical lead time for PCB assembly? Do you support rush orders?

Sample assembly orders are typically 3-5 days; small batches 5-7 days; large lots 7-10 days. Rush service is available, with some sample orders shipped as fast as 24 hours. We’re happy to discuss what timeline you have in mind for a specific rush request; contact our customer service and we’ll be happy to assist!

6、What quality inspections are performed after PCB assembly?

Full inspection process: 100%.

① Automated Optical Inspection (AOI), catching cold solder joints, missed solder, wrong components, etc

② Electrical Testing (E-test) and verification of circuit continuity and insulation

③ Functional Testing (FCT) and parameter debugging for customized controllers like lighting boards

④ Manual sampling inspection of solder joints and interface stability to IPC-A-610 Class 2/3

7、Can customized assembly solutions be provided for special applications (i.e., aquarium lighting control boards)?

Yes! There are custom requirements we support based on product applications:

① Aquarium lighting control boards / drivers: Parts are selected based on temperature resistance properties, and solutions for heat dissipation optimization techniques can be provided.

② Precision control devices (example, sensor modules): Parts placement accuracy ±0.02mm

③ Close work with you for parameter debugging on PCBA compatibility across an entire end-device.

Inquiry

Free existing samples or similar-function pcba or solutions for reference.

sales development:

- sales@huasunpcb.com

- +86-13826586481

Support

Professional one-stop service for PCBA from design to production.