Turnkey PCB Assembly

Turnkey PCB Assembly – From Design to Finished Products, One-Stop Solution!

- Free DFM/DFA Check for All Projects

- 3-Day Prototyping Turnaround for Small Batches

- 99.9% Assembly Yield with AOI & X-Ray Inspection

- 10000+ Component Partners for Global Sourcing

- MOQ 1 Piece | Scalable to 100,000+ Mass Production

- Full Coverage for Consumer, Automotive & Industrial Electronics

What is turnkey PCB assembly service?

With HUASUN’s Turnkey PCB Assembly you can rest easy knowing that we’ve taken your idea from concept to realization.We’ll take care of precision component matching from a selection of more than 100,000 types and place components with micron-level accuracy.Following assembly,we’ll go through 3 rounds of quality inspection.We have a fully operational production line with a daily capacity for 500,000 boards.From a single prototype for R&D or a bulk order of millions,we’ve got you covered.We also deal with special processes that involve high and low-temperature processing ranging from-40°C to 125°C.

We save you 80%on the cost of supplier communications,source the components through their OEM’s to avoid counterfeit,and prevent production delays from manufacturing defects through our professional engineering optimization services.This brings your time-to-market down by 20-30 days and eliminate pain points that are common in the industry such as high premiums for small purchases,component substitution features,and no traceability for quality.

Our Main turnkey PCB manufacturing Service

Turnkey PCB Assembly is a one-stop shop service providing PCB Assembly and components sourcing. Its core service includes these 6 modules, completely satisfying the customers’ need to “simply say what is required and await delivery of the complete product.”

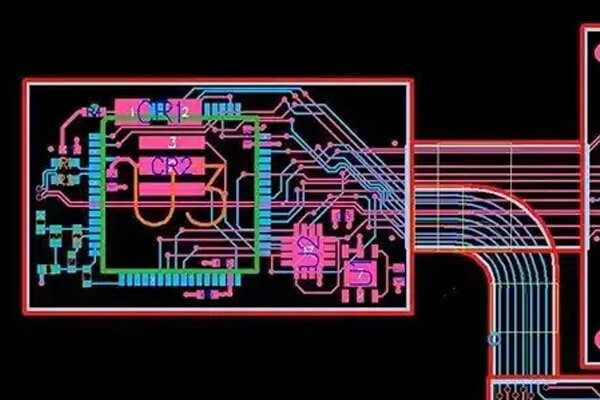

PCB Design Services

Complimentary DFM/DFA manufacturability analysis proactively identifies potential production and assembly challenges in design drawings, accompanied by recommended process optimizations to avert postponing rework.

PCB Manufacturing

Manufacturer of blank circuit boards, custom-made to individual specifications, in multiple layer counts, materials and processes, fol all performance requirements for applications including consumer electronics, automotive, industrial control etc.

Component Sourcing

We provide over 100,000 models of components from chips to capacitors, resistors to connectors, and more. Factory-sourced. Authenticity guaranteed. Alternative part number sourcing solutions available for stock shortages.

SMT Assembly and Manufacturing

All-in-one assembly process utilizes automatic component placement and cleaning with assured micron-level accuracy, meeting requirements for all volumes, from prototyping 1 piece, to more than 1 million pieces.

Multi-Dimensional Inspection

Multi-level quality check via three or more inspection phases. Including AOI optical inspection, X-ray inspection, and functional testing. Achieving a yield soldering yield rate of over 99.9%. Supply quality reports with full traceability reports.

Delivery & After-Sales

Fast prototyping delivery in 3 days. Batch delivery in 7-10 days. Customize packaging on request. Provide after sales support for technical enquiries, and resolve problems occurring during product application.

Why Choose HUASUN turnkey PCBA Service?

We are the trusted partner of Fortune 500 companies for both rapid prototyping and large-scale volume production needs.

expert engineering

A specialist team for all your complex layouts, signal integrity or manufacturing design issues

smart pricing

Volume pricing, competitively priced with value engineering not just on first orders but for life.

certifications

ISO 9001, ISO 13485, IATF 16949…RoHS, REACH and UL applicable to your regulated industry

secured logistics

A global secure supply chain and storage solution, plus long lead-time strategic sourcing

high-volume capacity

Low-cost volumes with the ability to accommodate increases and decrease in volume

HUASUN turnkey PCB assembly Process

| Specifications | Details |

|---|---|

| Layer : | 1-40 layers |

| Material: | Base KB、 Shengyi、 ShengyiSF305、 FR408、 FR408HR、IS410、FR406、GETEK、370HR、IT180A、Rogers4350B、 Rogers4000、 PTFE Laminates(Rogersseries、 Taconic series、 Arlon series、 Nelco series)Rogers/Taconic/Arlon/Nelco laminate with FR-4material(including partial Ro4350B hybrid laminatingwith FR-4) |

| Board Type : | Backplane、 HDI、 High multi-layer、 blind&buriedPCB、 Embedded Capacitance、 Embedded resistance board、 Heavy copper power PCB、 Backdrill. |

| Board Thickness : | 0.2-5.0mm |

| Copper Thickness: | Min. 1/2 0Z,Max. 10 0Z |

| Min.Spacing/ Tracing: | 2.7mil/2.7mil |

| Solder Mask: | Green, Black, Blue, Red, White, Yellow,Purplematte/glossy |

| Surface Treatment: | Flash gold(electroplated gold)、 ENIG、 Hard gold.Flash gold、 HASL Lead free、 OSP、 ENEPIG、 Softgold、 Immersion silver、 Immersion Tin、ENIG+OSPENIG+Gold finger,Flash gold(electroplated gold)+Gold finger,lmmersion silver+Goldfinger,lmmersion Tin+Gold finger. |

Type of turnkey PCB

Rush PCBA Prototyping

——PCBA Rapid Prototype | 24H Expedited Service | 1 Piece MOQ

- Lead Time Express: Standard delivery in 3 to 5 days, expedited to 24-hour delivery. (for existing standard processes only goes).

- Rapid Response: Getting Design for Manufacturability feedback in 4 hours.

- No MOQ:(Prototype manufacuring is available even in 1 piece, and can be expedited through standard process for small batches).

- Quality Assurance & Speed: Fully automated production lines + parallel work; expedited orders go through standard manufacturing processes.

- Guarantee: Technical NDA’s with every classified project for us; end-to-end encrypted design files with internal access controls.

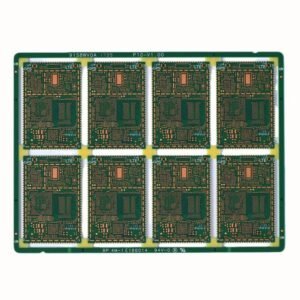

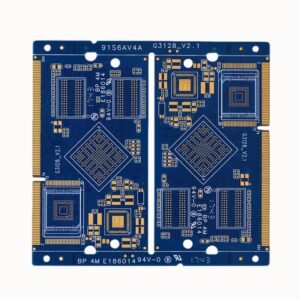

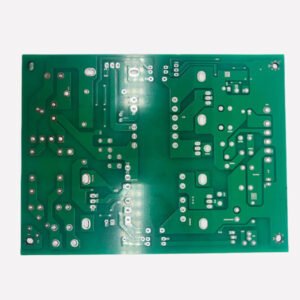

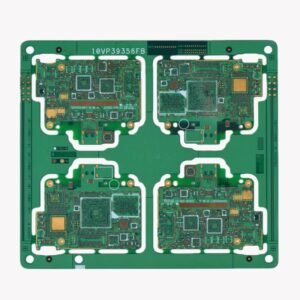

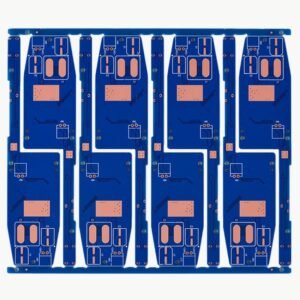

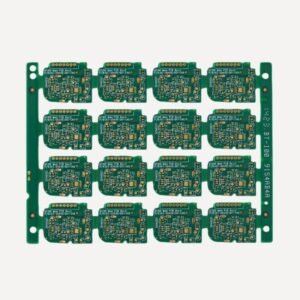

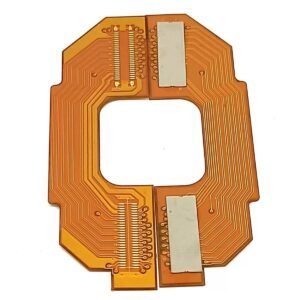

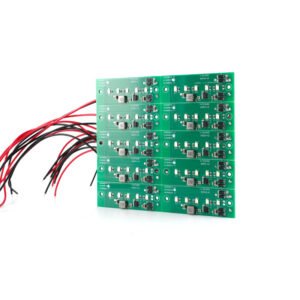

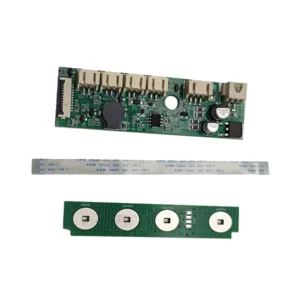

turnkey PCB assembly Case

Printed Circuit Board Turnkey FAQ

1. How is Turnkey PCB Assembly different from Full Turnkey PCB Assembly?

They’re both one-stop services:

Turnkey PCB Assembly: A budget one-stop service(containing just your basic needs), covering PCB prototyping, component sourcing, SMT Pick and Place assembly, and testing and delivery. Best used for companies possessing some components of the PCB supply chain but have standard requirements.

Full Turnkey PCB Assembly: An even more healthy-sized package containing your globes needs. In addition to the basic plan, a Full Turnkey PCB Armada contains DFM/DFA design correction free of charge, component substitutive solutions, technicians support after purchasing, price breaks on volume purchases, and even assistance in product certification through appropriate regulatory channels. Best of all for companies with no experience of production.

2. What services are in Turnkey PCB Manufacturing?

3. What is MOQ? Do you provide rapid prototyping?

Our Turnkey Prototype Assembly offers a ridiculously low MOQ of 1 piece, assisting your projects’ R&D prototyping and small batch testing. We do offer rapid services, turning around the entire process—from PCB manufacturing and sourcing components, to an assemble PCB—including first-article inspection report in as few as 3 business days.

4. What types of industry products need Full Turnkey Assembly?

Products from the consumer-durable sector (power banks, mood lights, small appliance electronics); industrial productsRoute Automotive electronics (vehicle controllers); industrial control (PLC mainboards); portable medical devices (detectors).

Production processes and inspection procedures can be tailored to meet locality-compliance and required the therapy. (ie Automotive-grade; medical-grade).

5. What factors affect pricing of Full Turnkey Assembly?

PCB: Material of PCB, layer count, terms of PCB surface to be manufactured and assemble e.g FR-4/aluminum substrate? Number of layers? Area? Manufacturing Complexity? Impedance control? Blind/buried vias?

Components: Part-several Rarity, package size? 01005/BGA along with-firm manufacturing compliance-Do you want a choice of brand? Original manufacturer parts or alternative parts?

Order Quantity: Small-batch prototyping— 1~100 pcs; please note; 10,000 pcs + unit costs drops per order!

Are there special requirements? Peruse! Is conformal coating desirable? Special Automotive? or possibly Medical grades? or Low/ High Temperature testing

6.What are the lead times for small-batch and mass production?

Standard lead times are as follows:

Small-batch prototyping(1-100 pieces):3-5 business days;

Medium-batch orders(100-1000 pieces):5-7 business days;

Mass production(1000+pieces):7-15 business days,adjusted based on order volume.

Rush services are available,with samples ready as fast as 24 hours(for simple processes only).A small rush fee applies.

7.Are there charges for modifying the BOM list or PCB design?

Before PCB production:Modifying the BOM or design requires only re-verification of materials and incurs no additional fees,with a 1-2 business day extension to the lead time.

During PCB production/after component procurement:Changes incur PCB scrap costs and component return/replacement fees,extend delivery by 3-5 business days,and require a new quotation;

Assembly stage:Changes are strongly discouraged as they may result in scrap of semi-finished products,causing significant cost and delivery delays.

8.How do you ensure procured components are genuine OEM parts?

Procurement:All components are sourced directly from original manufacturers or authorized distributors.We do not use refurbished,substandard,or defective parts from traders.

Incoming Inspection:Upon arrival,components undergo part number verification,visual inspection,and functional sampling.Non-conforming items are immediately returned.

Delivery Documentation:We provide original manufacturer COC/COA certificates,batch test reports,and copies of purchase invoices upon shipment.We support third-party verification by customers.

Inquiry

Free existing samples or similar-function pcba or solutions for reference.

sales development:

- sales@huasunpcb.com

- +86-13826586481

Support

Professional one-stop service for PCBA from design to production.