PCB Assembly Prototype

Custom PCB Assembly Prototypes – Ready for Mass Production

HUASUN is a professional PCBA manufacturing facility. We specialize in providing customers with one-stop prototyping services that cover everything from conceptual ideas to finished PCBA boards!Whether you only need an initial creative concept or already have a preliminary design plan, we can support you with end-to-end one-stop solutions to bring your project to fruition every step of the way.

What is PCB Assembly Prototype?

PCB Assembly Prototype refers to the “sample trial production” phase in electronic product development. It involves soldering components (chips, resistors, capacitors, etc.) onto blank PCB boards based on customer design files (such as Gerber files and BOM lists), creating a small batch (typically 1-100 units) of functional prototype boards for testing and verification.

Simply put, it transforms your “design blueprint” into a “functional prototype.” For instance, if you envision a small device (like a smart lamp or mini speaker), even with just an idea or basic sketch, we can solder components like chips and resistors onto a dedicated circuit board (PCB) to create one or several ready-to-use samples. No need to jump straight into mass production.

Test these samples first to verify usability and functionality. Make adjustments anytime if issues arise. Only proceed with bulk production once everything is confirmed—saving both time and money.

Our Main PCB Assembly Prototype

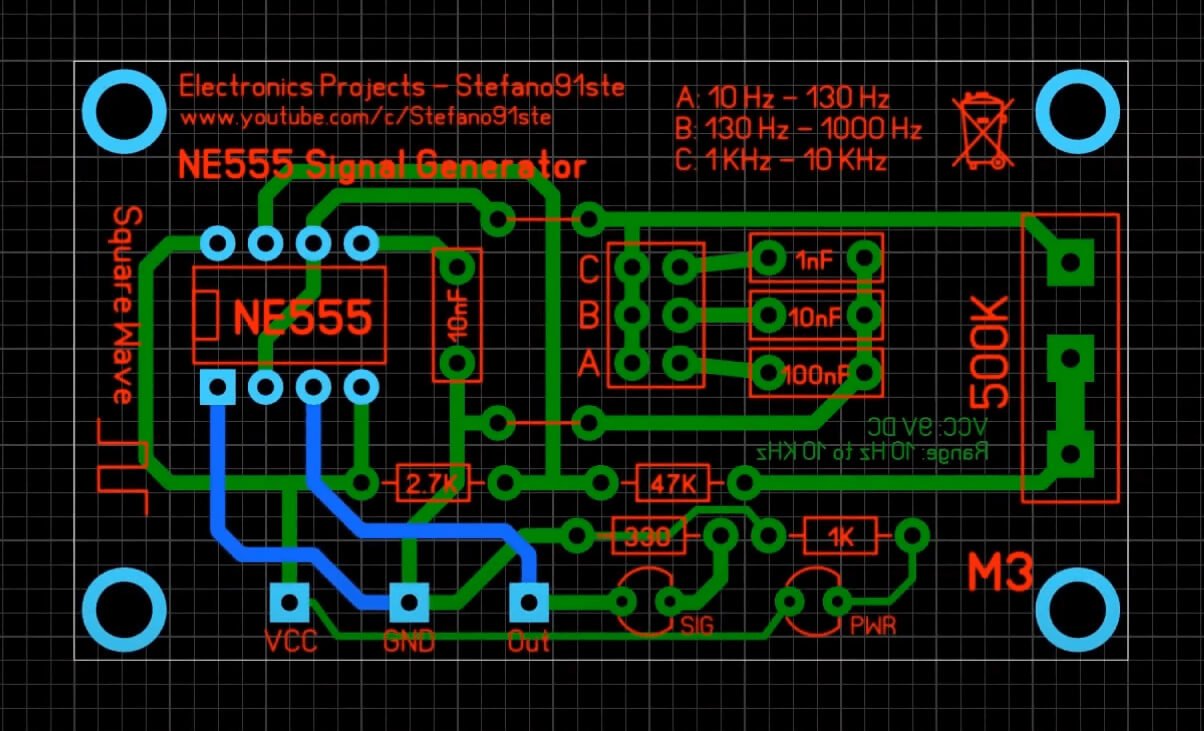

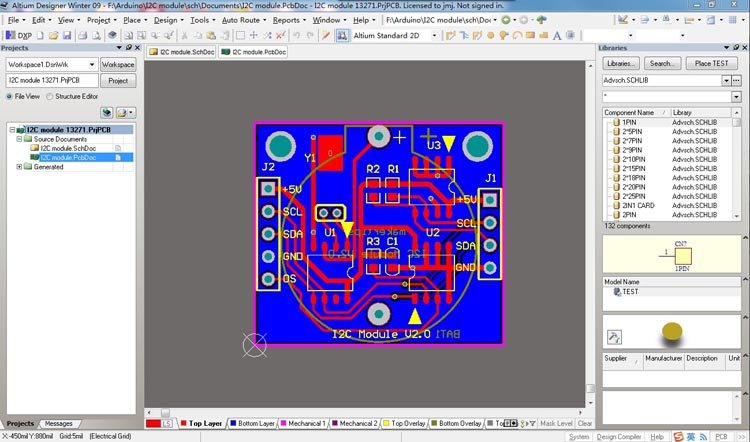

Prototyping from Design Files

Want to start from an existing set of design files (Gerber & BOM)? We prototype directly from your files—reproducing what you’ve specified—without changing the design.

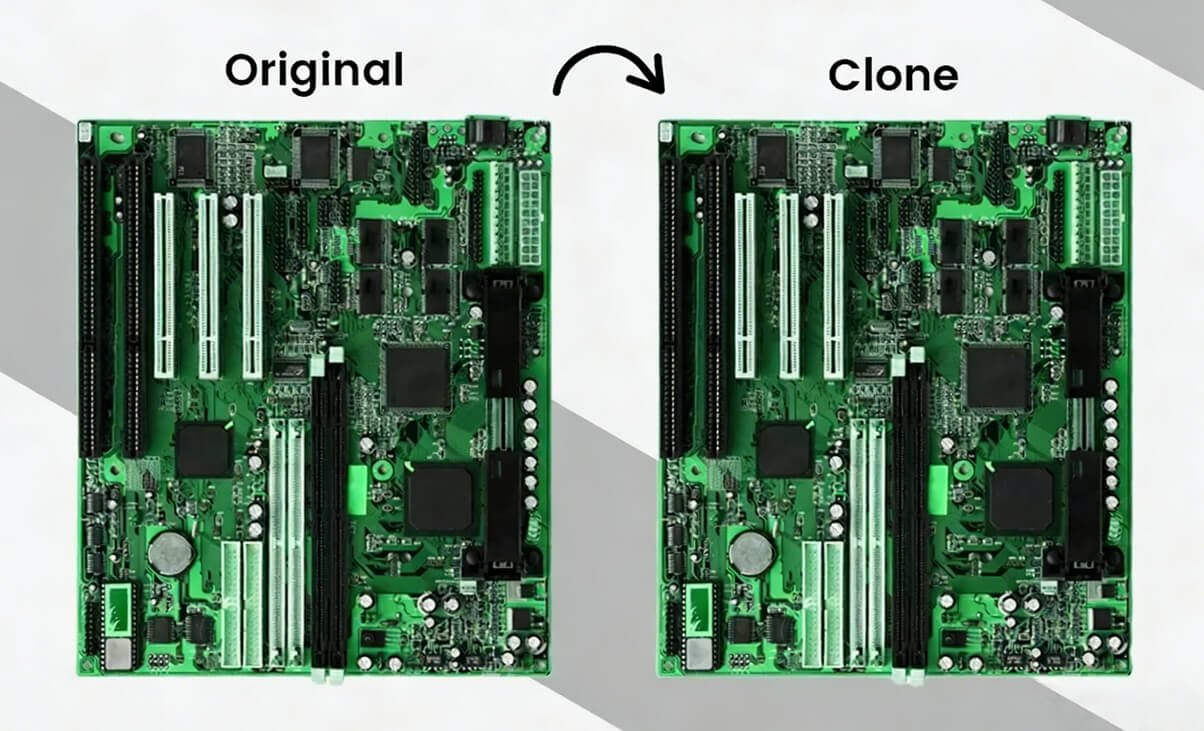

PCB Cloning Prototype

You’ve got a proprietary PCB you want to clone/duplicate? We reverse engineer the design to replicate the original board in a functional sample.

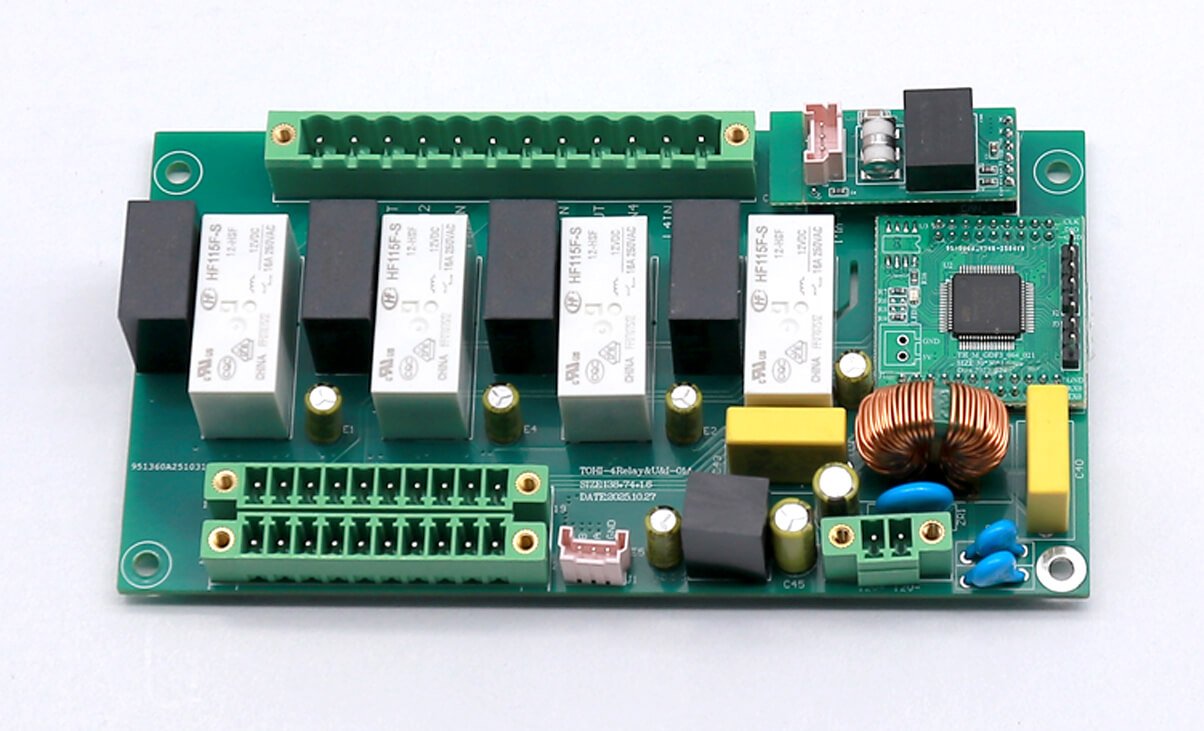

Custom PCBA Prototype

You have an sample/old design that works very well, but have to change or adapt the function of the hardware? We adapt the existing design for you, no complete redesign needed.

Small-Batch Trial Production

You’re not ready to dive into the deep end? We will help you decide “whether mass production can be done” after your sample is validated.

Why Choose HUASUN PCB Assembly Prototype Service?

Get 50% OFF assembly labor costs on your first order – savings up to $250!Valid only for new company customers. Additional terms & restrictions apply.

Rapid Prototyping

Simple prototypes finished in one day; difficult ones within two to three days ( tackling R&D time-critical issues)

Quality Assurance

The highest quality standards are upheld through the systematic testing and inspection of every PCB assembly.

Competitive Pricing

Open quotes with no extra fees; component substitution suggestions provided (lowering R&D costs)

Process Advantages

Helping with the tiniest packages (like 01005, 0.4pitch BGA), placement accuracy (±0.03mm), soldering success rate (≥99.8%), etc.

Flexible Customization

Helps in small-scale, multi-version prototype iterations. Response to design changes quickly without incurring major additional costs.

PCBA Prototyping Quality Control

————Full-process Quality Control of PCBA Prototyping

- IQC Incoming Material Inspection: For PCB substrates and electronic components, conduct two verifications to check if they are authentic.

- Multi-stage IPQC Patrol Inspection: AOI optical inspection equipment automatically identifies things like misalignment, missing components, and incorrect placement.

- Finished Product Testing: Power-on functional tests and withstand voltage tests on finished products, sampled at 30% or more of each batch.

- Sample Quality Records: Each sample board has a separate batch number, so return visits may see the production date, equipment parameters, and operator.

PCBA Prototyping Process

1. Customer Inquiry

Customers submit PCBA Gerber files and specification requirements.

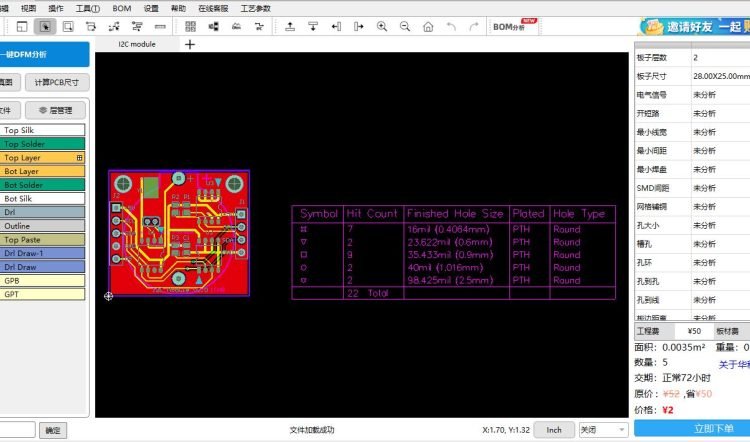

2. DFM Analysis

Engineers complete DFM (Design for Manufacturability) analysis and provide feedback within 2 hours.

3. Prototyping PCBA

Substrate Preparation, Circuit Trace Fabrication, Surface Finishing, and other related processes

4. Quality Check

final check. pcba samples are then cleaned, dried, packaged, and prepared for shipment.

Type of PCB assembly prototyping

High Precision Multilayer PCB

RF Microwave High-Frequency PCB

Heavy Copper PCB

Ultra Heavy Copper PCB

Controlled Impedance PCB

FR-4 PCB

HDI (High Density Interconnect) PCB

Castellated Hole PCB

Gold Finger PCB

Rigid-Flex PCB

FPC (Flexible Printed Circuit) Board

Copper Base PCB

Rush PCBA Prototyping

——PCBA Rapid Prototype | 24H Expedited Service | 1 Piece MOQ

- Lead Time Express: Standard delivery in 3 to 5 days, expedited to 24-hour delivery. (for existing standard processes only goes).

- Rapid Response: Getting Design for Manufacturability feedback in 4 hours.

- No MOQ:(Prototype manufacuring is available even in 1 piece, and can be expedited through standard process for small batches).

- Quality Assurance & Speed: Fully automated production lines + parallel work; expedited orders go through standard manufacturing processes.

- Guarantee: Technical NDA’s with every classified project for us; end-to-end encrypted design files with internal access controls.

PCB assembly prototyping Specifications

| Specifications | Details |

|---|---|

| Types of Assembly: |

THD (Thru-Hole Device); SMT (Surface-Mount Technology); SMT & THD mixed; 2 sided SMT and THD assembly. |

| Order quantity: | 1 to 50,000 boards |

| Component: |

Passives parts, smallest size 01005; Fine pitch to 8 Mils; BGA, uBGA, QFN, POP and Leadless chips; Connectors and terminals. |

| Component Package: | Reels; Cut tape; Tube and tray; Loose parts and bulk. |

| Board dimensions |

Smallest size: 0.2" x 0.2"; Largest size: 15" x 20". |

| Board type: | Rigid FR-4; Rigid-Flex boards. |

| Design file format: |

Gerber RS-274X; BOM (Bill of Materials) (.xls, .csv, . xlsx); Centroid (Pick-N-Place/XY file). |

PCB assembly prototyping Case

Communication Product Mainboard SMT Assembly and Through-Hole Component Testing

Network Router SMT Through-Hole Component Soldering Test

Vehicle Monitoring Mainboard SMTThrough-Hole Component Test for Municipal Sanitation Vehicles

Communication Product Mainboard SMT Assembly and Through-Hole Component Testing

Panoramic Camera Mainboard SMT Assembly Testing for Export to Dubai and Japan

Electronic Tag Bluetooth Product SMT Assembly

Vehicle Air Purifier SMT Assembly and Through-Hole Component Assembly

FAQ

1. Can you handle high-density, fine-pitch PCBA prototyping? For example, assembly of 0201 package components and 0.4mm pitch QFP chips?

Absolutely! We support high-density, high-quality PCBA prototyping. Our factory is equipped with ultra-high-precision placement machines (min placement accuracy is ±0.03mm) and can easily handle ultra-wide array of processes including 0201/01005, vey small packages, 5.0mil pitch QFP/BGA, and PoP stacked packages. We provide DFM (Design for Manufacturability) reviews pre-prototyping to ensure the design is matched to the production capability.

2. What is the shortest turnaround time for PCBA prototyping? Do you offer expedited services?

3. Do you accept small-batch prototyping (e.g.1-10 pieces)? Is there a minimum quantity requirement?

Yes, we welcome PCBA prototyping and other small-batch prototyping with no minimum quantity requirement (one piece is fine, custom quotes available). On very small orders, the qualified assemblers in our factory will optionally maximize their lower costs for in-stock goods on the small order, producing your design using the same techniques and process quality we would use for a mass-order. This means you’ll be ready to move directly into volume at any production factory with the previous small-batch run.

4. What does the prototyping quote include? Are there hidden costs (e.g. engineering fees, testing fees)?

The pricing included in the quote is entirely transparent as is all work we do - we detail PCB fabrication fees, component procurement fees (if we are procuring them for you), assembly, standard testing fees (AOI/X-Ray and others), packaging and shipping cost (we calculate based on what you tell us your preference is for this), and such. No hidden costs. All miscellaneous fees (such as stencil fees, programming fees, quoted. Some of these engineering fees may be waived in the case of production work.

5. Can the factory accommodate my components if I supply them? How do I get assurances that they are secure?

Yes, we support CM services. Upon receipt of your components, we do:

①familiarization and inspection vs. your supplied BOM;

②sealed off storage bearing your name and project number;

③dedication of key personnel throughout production. Your remaining components are returned with the goods and are accompanied by a detailed report of usage to confirm that none have been lost or misplaced.

6. If I need to revise the design while developing the first prototype, will the factory be able to do this? Will there be additional charge?

We can accommodate design changes, subject to your submission of a formal Engineering Change Notice (ECN) request. If they are completed before your product is put into production (before any components are bought, or stencil made), there is no charge typically. If work has already begun, for example, components mounted or stencils made, there may be a small rework fee or material loss fee which we will agree with you beforehand according to how heavily the design is changed (that is, number of components swapped, pads re-size, etc).

7. I have a confidential project, will your factory sign a Non-Disclosure Agreement (NDA)?

We gladly support this. We make it a point to protect the commercial secrets of clients, from design and re-design solutions, down to documentation. We will sign a standard NDA agreement at a minimum (or accept one you provide yourself) with terms to suit you. We have an internal data confidentiality system where a design file can only be accessed by certain authorized personnel. At the end of the project, we erase information on request, and never pass your data to any person outside our firm.

Inquiry

Free existing samples or similar-function pcba or solutions for reference.

sales development:

- sales@huasunpcb.com

- +86-13826586481

Support

Professional one-stop service for PCBA from design to production.